|

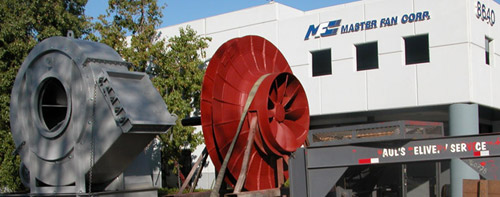

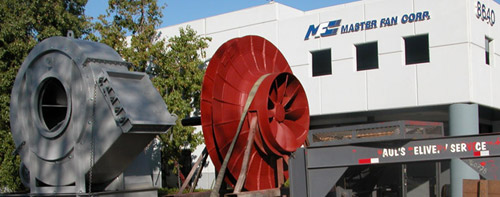

This Thermal Oxidizer Exhaust Fan was designed with self monitoring equipment so when the vibration reached the preset limit the fan shut down to prevent breakdown.

Master Fan Corp. was called in to asses the problem. With vibration analysis it was discovered that the inboard bearing was developing wear on the outer race. By trending we calculated that the fan would be run for a short time with reasonable safely until the next scheduled shutdown, two months away. The vibration limit switches were adjusted to allow the fan to run with some vibration. All spare parts were checked and some corrections made to parts. We were now ready to begin repairs at a moments notice.

The Fan ran until the scheduled shutdown. At that time it was decided that both bearings would be replaced with the new spares. The shaft was cleaned, checked for straightness and size and reused. After inspection of the original Impeller, it was decided that the installation of the spare impeller was not necessary at that time.

The repaired fan was precision aligned, trim balanced and placed back in service. The safety vibration switches were reset to specifications. The Fan ran perfectly. Most importantly, no unscheduled down time was required thus saving dollars with no lost production.

|